Geospatial Division Manager

We’re excited to introduce Brian Sumner, the Geospatial Division Manager at CFB. Brian has been with CFB since May 2022 and brings a wealth of experience and passion to his role. We sat down with Brian to learn more about his journey, his current role, and the fascinating world of drone-based geospatial data collection.

Brian: My main tasks are focused on fostering the growth and development of the Geospatial team, particularly in light of the introduction of new equipment and software. I oversee the initial point cloud processing and troubleshoot any related challenges. Additionally, I manage feature extraction across all ongoing projects.

Brian: I have been a licensed drone pilot for approximately nine years. Initially, my interest was just curiosity, but it quickly evolved into larger aspirations once I saw what was possible.

Brian: The geospatial process has quite a few moving parts. When a new project is assigned, we receive a file outlining the entire survey area. Using this file, I develop a plan for placing ground control targets strategically to ensure adequate coverage for the project’s size. This plan is then dispatched to our field crew, who set the targets as closely as possible to the original plan. The crew captures data by shooting these targets twice using conventional field methods, providing precise coordinates for each ground control point.

Following the ground control setup, the crew uses the same base station to conduct drone and Lidar scanning flights over the entire site. Altitudes and lateral strip separations may vary depending on the project, but typically, we opt for an altitude of around 300 feet and a strip separation of 50 meters for safety and accuracy.

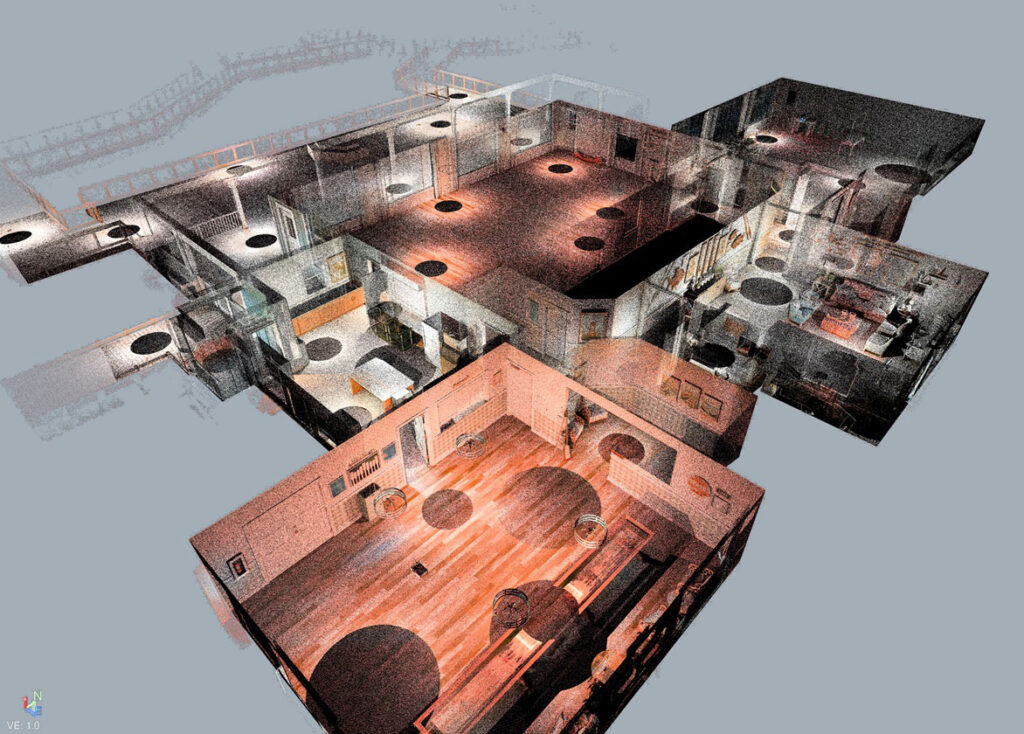

Upon completing the flight, the field crew returns to the office to transfer the collected data to our computer system. This data undergoes processing through various software packages, starting with trajectory processing before being imported into initial point cloud creation software that will be exported and brought into another software package for feature extraction. This is where all of the linework takes place, delineating various features such as curb faces, pavement edges, building corners, power poles, utilities, etc. Once all the improvements are drawn, a CAD file is exported and sent to the project manager to prepare the final deliverable.

Brian: Our primary drone is the Harris H6A Hybrid, equipped with a Riegl VUX12023 Lidar sensor. We also use several photogrammetry drones, including the Mavic 3 Enterprise RTK and the Phantom 4 RTK, for aerial imagery purposes. Additionally, we have a Trimble X7 static scanner for laser scanning smaller projects or building interiors/exteriors. This scanner can also supplement the airborne data, especially in obscured areas such as underneath bridges or overhangs. To ensure the equipment’s reliability and performance, we adhere to stringent maintenance protocols and provide comprehensive training to our operators on proper usage and upkeep.

Brian: Verifying that our operations are conducted in allowable airspace is crucial. We check various FAA maps for controlled airspace locations and altitude restrictions for each project. If we need to fly in restricted airspace, we communicate with the FAA and apply for a waiver. Sometimes immediate approvals are granted, depending on the airspace’s proximity to the restriction, but other times we have to coordinate with the control tower and possibly adjust our flight parameters to accommodate air traffic. We also diligently observe regulations pertaining to flying over people and/or traffic to uphold safety standards.

Brian: While incorporating drones and Lidar into every project isn’t realistic, there is a threshold for when drones become more efficient than using conventional methods. Typically, the larger the project, the better suited the drone is for efficiency. For example, if we have a one-acre commercial parcel that needed a topographic survey, a field crew can handle that much quicker than we can. However, if we have a 50+ acre site that needs topographic work, the drone becomes much more efficient and cost-effective compared to traditional methods. Each project, though, will always have some degree of conventional fieldwork needed as certain tasks like setting property corners require manual intervention. Additionally, some areas may prove too obscured for accurate data extraction, further highlighting the complementary nature of drones and traditional methods in geospatial data collection.

Brian: Once a job is assigned a Geospatial task in our project management software, I review the details and scope with the project manager. I then develop a flight plan tailored to the project’s requirements, ensuring adequate coverage for our objectives. Once the flight plan is established, the project manager is less involved other than keeping updated with scheduling. However, once the final feature extraction file is completed, it is forwarded to the project manager for review. Should any issues or questions arise, we will pull up the scan data and evaluate further steps together.

A benefit of using Lidar technology is our ability to revisit a project site virtually, eliminating physical site revisits. This capability allows us to address questions quickly. For instance, if there was a question regarding the presence of a manhole, we can easily load the data and very clearly see whether or not there was.

Brian: The current advancements in hardware and software are already mind-blowing. However, the deeper we dive into both, the more we see room for improvement. I expect there to be a growing gap between hardware and software capabilities. Currently, hardware is probably further along in development than the software side is. This means software should see significant improvements in its capabilities over the next few years. Coupled with the exploding growth of AI-related technologies, the feature extraction side of geospatial data collection should become increasingly more efficient and accurate.

Stay tuned for more insights from our team and behind-the-scenes looks at how we leverage modern technology to deliver top-tier solutions.

Do you have a project you’d like us to work on? Request a Quote!

CFB Ocala Has a New Home! Click for details.